The legal changes in electrical testing every landlord needs to know about

Changes in regulation relating to electrical testing could catch out commercial and private landlords and land them with large fines, says phs Compliance, the UK’s largest provider of electrical safety testing.

In recent years, legislation has not identified a mandatory timeframe for carrying out electrical testing on electrical installations and equipment, instead stating that duty holders must ensure electrical systems are regularly maintained and safe to use, leaving it to them to decide the most appropriate frequency for their tests.

By law, all domestic and commercial landlords must now have an Electrical Installation Condition Report (EICR) completed by a qualified person every 5 years to ensure the safety of their property for tenants. Failure to comply could cost lives and a sizeable fine.

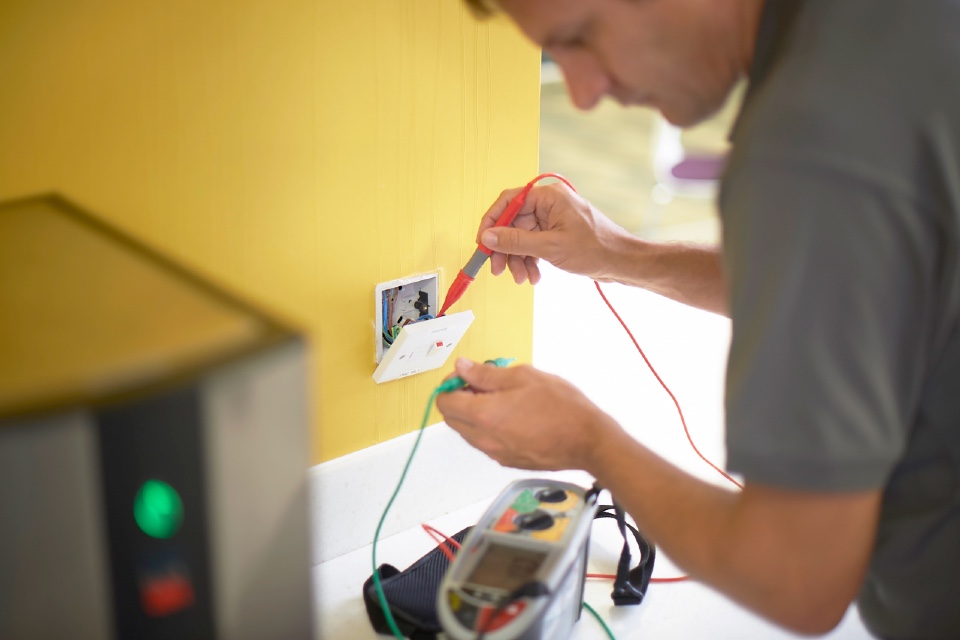

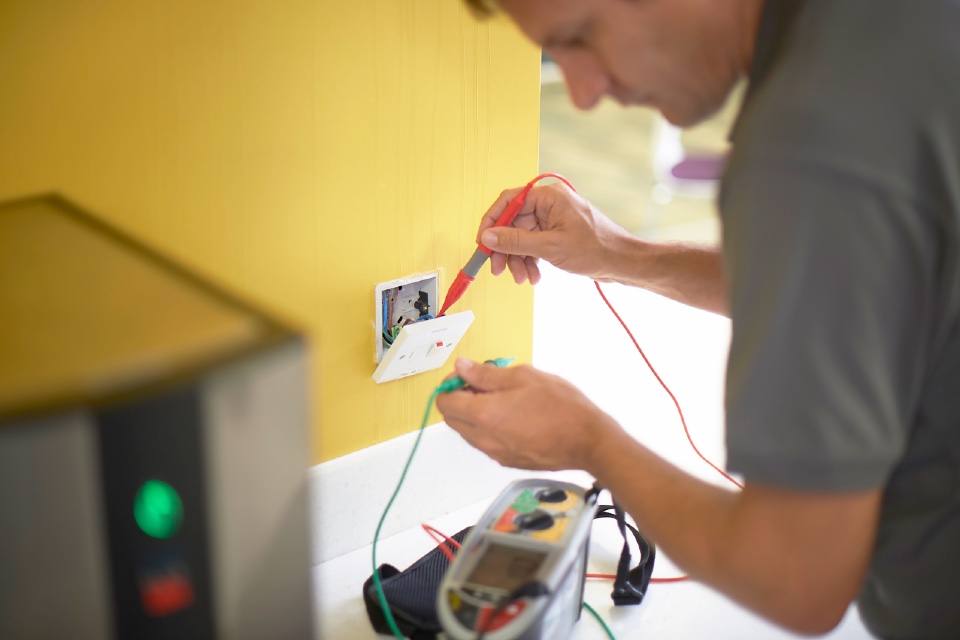

“This applies to all landlords and relates to electrical installations – that is all fixed electrical equipment that is supplied through an electricity meter including cables, accessories, like sockets, switches and light fittings, fuse boxes, circuit breakers and residual current devices,” says Tracy Burtwell, Managing Director of phs Compliance.

“The changes have not been widely publicised, so there is the danger that many landlords are not aware of them and are unintentionally breaking the law.”

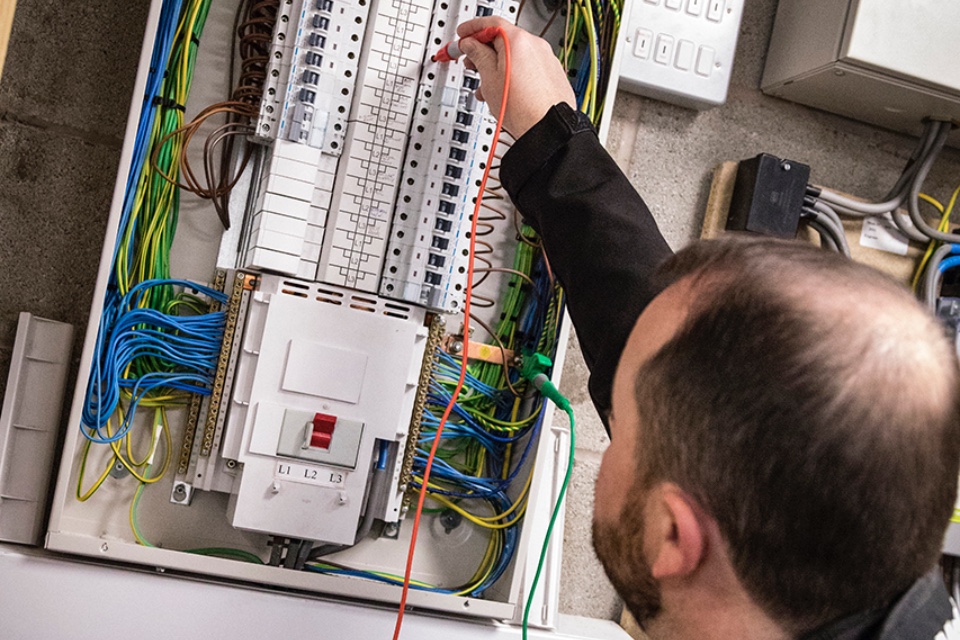

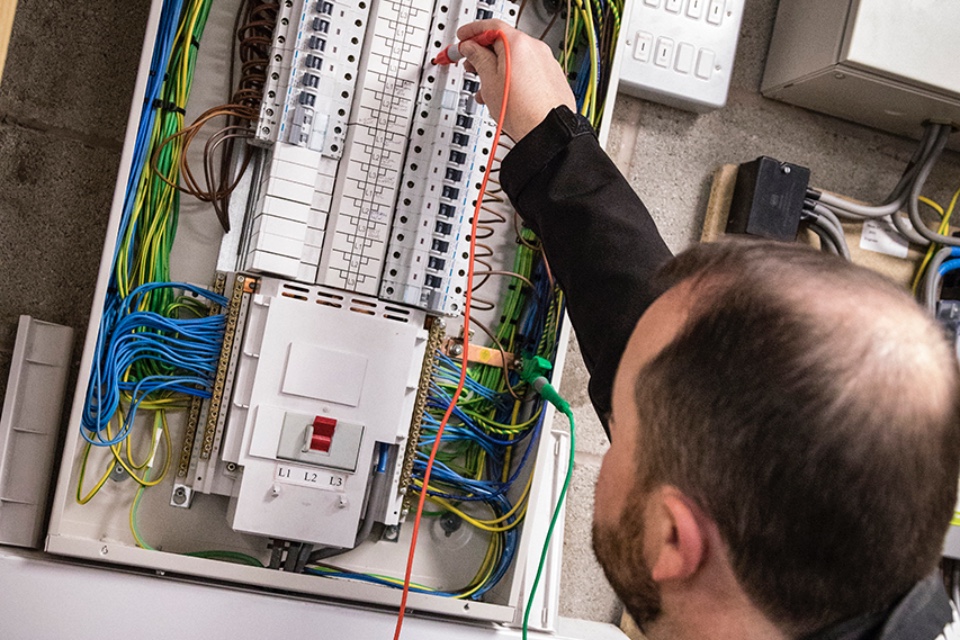

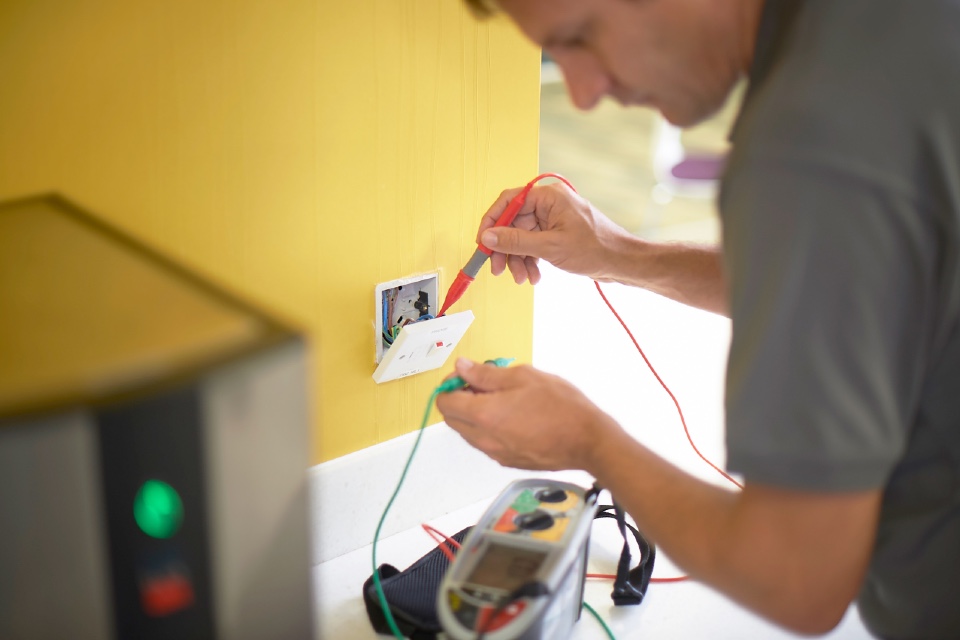

An EICR is produced following an assessment of an electrical installation in a building. This assessment inspects the installation, checks components for wear and tear and looks for faulty wiring and anything that could pose a risk. The results are recorded in an EICR and any unsatisfactory outcomes must be fixed and made safe before a satisfactory EICR is achieved.

“The law states that an EICR, which is also called a fixed wire test, must be carried out by a qualified person so we urge businesses to get in touch with us to ensure they are compliant,” says Tracy.

“Although the regulations stipulate a mandatory five year inspection, businesses may need an EICR more frequently in order to ensure they are meeting their health and safety obligations.

“As a guide, most offices, retail spaces, schools or care homes require less frequent testing – usually once every five years.

“However, a higher risk environment, like a swimming pool (exposed to high levels of moisture) or an industrial unit (with high dust levels), would require more frequent testing to ensure safety- usually every year.

“You should always consult a qualified professional to discuss the frequency of your electrical testing to ensure everyone’s safety.”

phs Compliance is an expert in commercial EICR inspections services. They are the UK’s largest and most experienced provider of EICR inspections, certifications and electrical safety testing, with a large, nationwide team of highly experienced engineers. phs Compliance has full regulatory and industry accreditation.

To learn more about phs Compliance’s EICR services or to book an inspection, visit the EICR Services page.